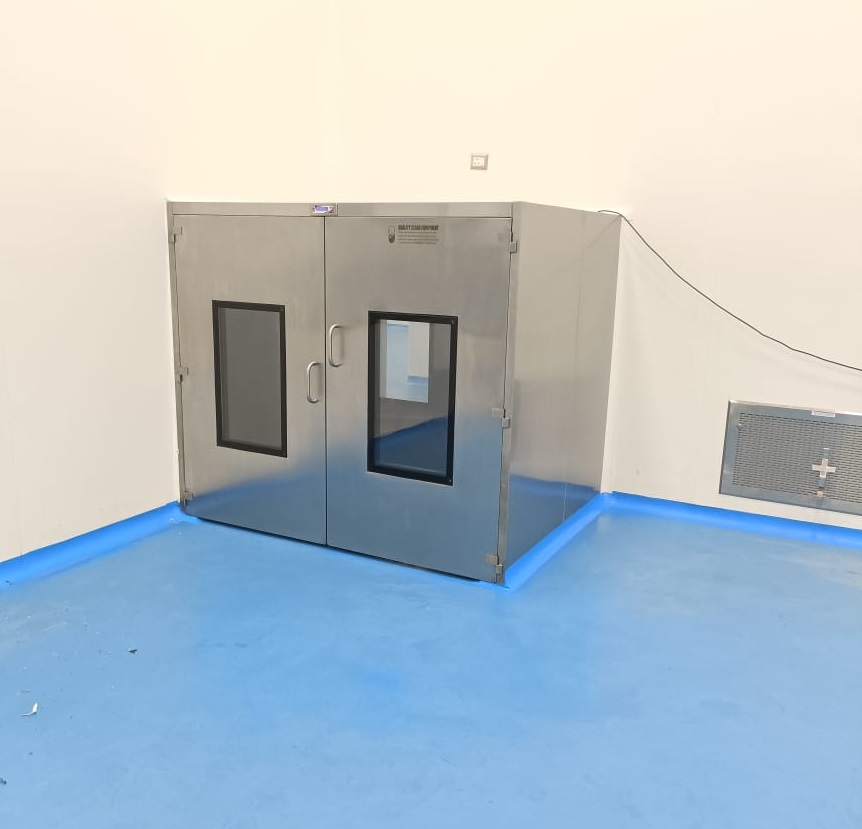

STATIC PASS BOX DOUBLE LEAF DOOR

Our Static Pass Box Double Leaf Door is suitable to avoid cross contamination between different classified are as & to maintain integrity of products & process while transferring material. Static Pass Box Double Leaf Door are used to transfer material without much personal movement between different classified areas and avoiding particulate contaminations.

A Static Pass Box with a Double-Leaf Door refers to a type of Static Pass Box Double Leaf Door that has two doors on one side of the equipment. These doors are often referred to as “double-leaf” doors due to their design. This configuration is commonly used in controlled environments to facilitate the transfer of materials between different areas while maintaining the integrity of the controlled environment and minimizing the risk of contamination.

The choice between a Static Pass Box Double Leaf Door with a single door or a double-leaf door depends on factors such as the facility’s layout, workflow, and the volume and type of materials being transferred. The goal is to maintain the controlled environment and minimize the risk of cross-contamination during material transfer.

Description

Description – Static Pass Box Double Leaf Door

| MOC | SS 304, 1 MM THICKNESS (MAKE-: JINDAL STEEL) |

|---|---|

| DOOR | SS 304, 1 MM THICKNESS DOUBLE WALLED DOOR CONSTRUCTION WITH FLUSH GLASS VIEW PANELS WITH SS HANDLES AND SS HIGNES |

| FLP INTERLOCKING |

FLP ELECTRO-MAGNETIC INTERLOCKING TYPE DOOR ARRANGEMENT TO ENSURE THAT ONLY ONE SIDE DOOR CAN BE OPENED AT ANY GIVEN TIME (MAKE-: INSTEC INDIA/ SINGH AUTOMATION) |

| DOOR INDICATIONS |

INDICATORS ON EITHER SIDE FOR DOOR OPEN CONDITION |

| DOOR RELEASE | DOOR RELEASE SWITCH ON EITHER SIDE |

| FLP UV Light & LED Light |

FLP UV & FLP LED LIGHT, Make:- Philips |

SERVICE

1. Installation-: furniture & equipment installation Provided by our company , our site engineer installed all

the machines and furniture as per requirements.

2. Validation-: validation also provide by our company repetitive team done. Customer site location or before

Dispatch the machine at our factory location validation Done . Depends on client requirements.

3. Transport-: as per client requirement transportation Arrange by our team also courier the material through by Road or by air.

4. Site engineer-: in case any issue come to the machine our Engineer will be visit in next day in customer site(depends On customer location).

APPLICATION

| 1. Pharmaceuticals & bio technologies clean room | 6. Hospital |

| 2. Chemical industry | 7. Radiological contamination |

| 3. Food industry | 8. Medical device clean room |

| 4.Chemical lab | 9. Microelectronics nanotechnology |

| 5. Institute | 10 .Life sciences |

SERVICE AREA

LOCATION:

| VASAI | VAPI | DAMAN | HARIYANA | GOA |

| ANDHERI | BARAMATI | AHMEDABAD | HARIDWAR | RAJASTHAN |

| THANE | NASHIK | KOLKATA | SIDDCUL | UDYAPUR |

| TALOJA | DAHEJ | CHENNAI | SIKKIM | HYDERABAD |

| PALGHAR | SURAT | BENGALURU | INDORE | TURBHE |

| BOISAR | VADODARA | BADDI | UTTAR PRADESH | HINJWADI |

Reviews

There are no reviews yet.